Services

Industrial Design

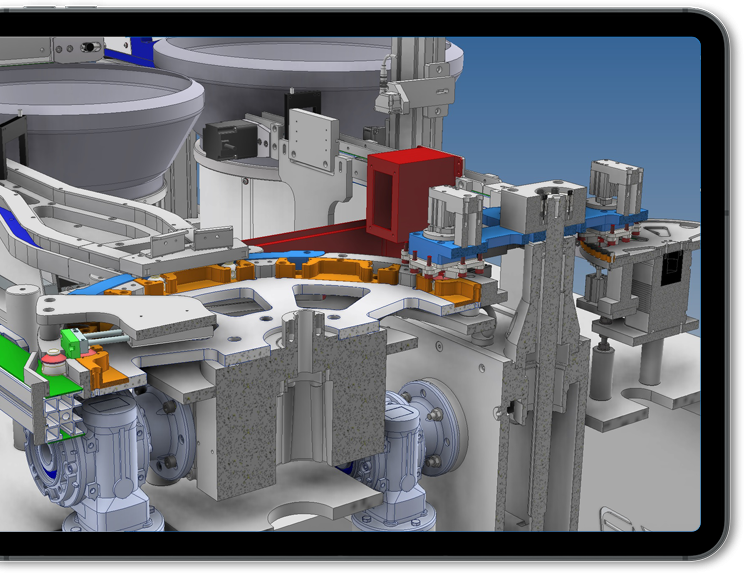

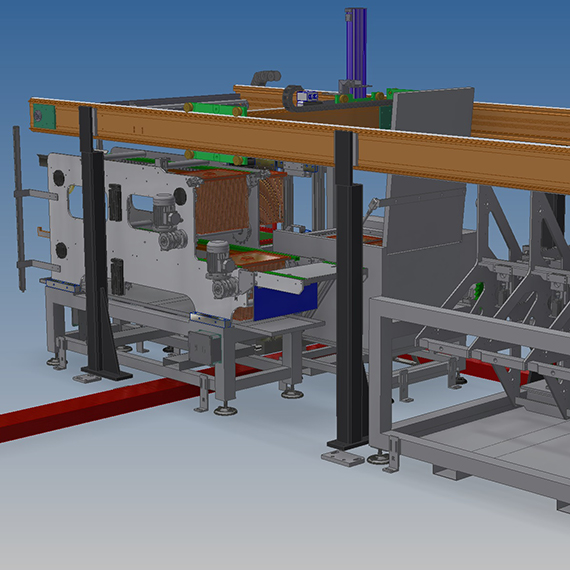

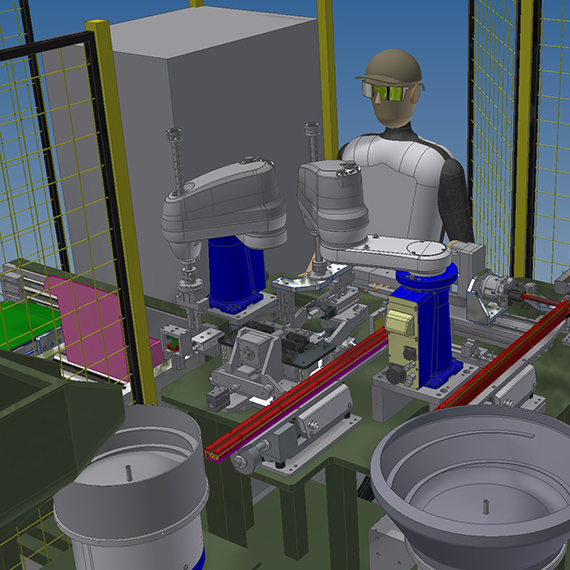

The industrial design of all solutions that the company offers is carried out internally, thanks to a technical office made up of designers and qualified technicians, who provide their expertise to develop customer requests at every stage of the design: from the analysis of needs and objectives to the identification of the best solutions.

Custom

Industrial Design

The team of our technical office is able to develop customized projects, organizing all stages of the project to optimize times and costs, in compliance with the regulations governing the design, construction, and safety of machines.

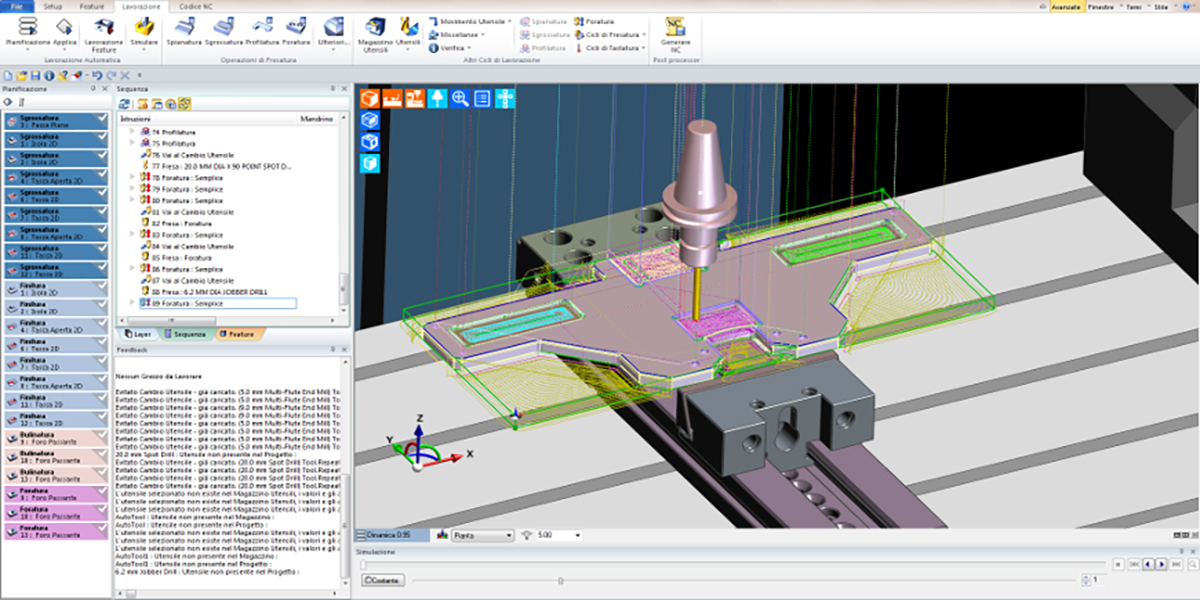

CAD-CAM

Industrial Design

Osca Automazioni is capable of realizing the final project requested by the customer, using CAD-CAM technologies (such as INVENTOR and EDGECAM), from which it is possible to move to the implementation phase.

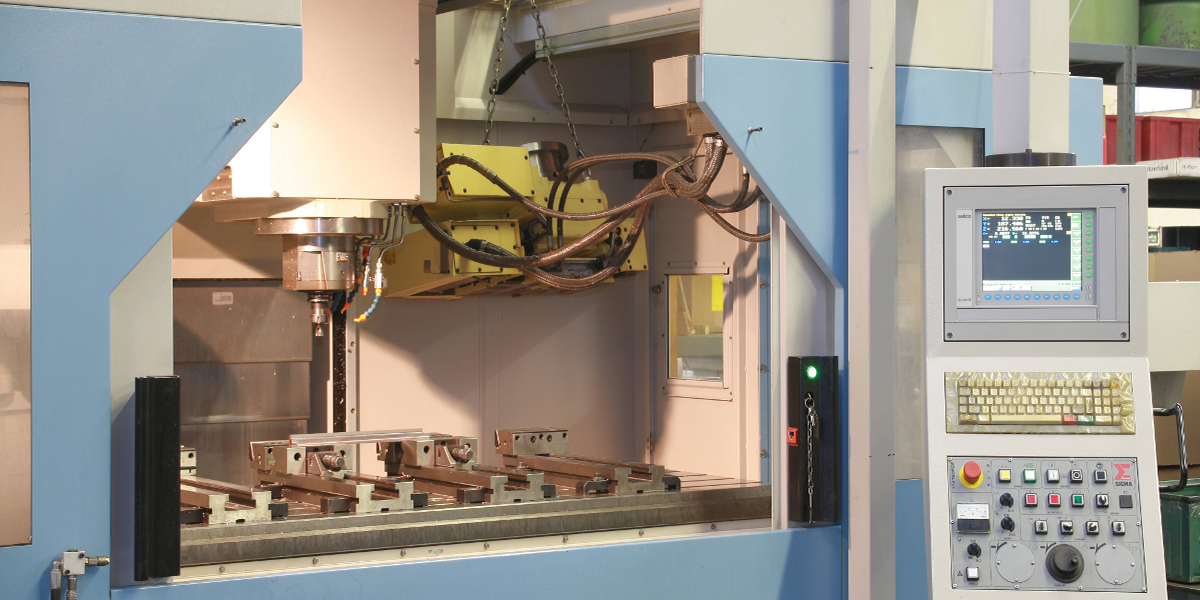

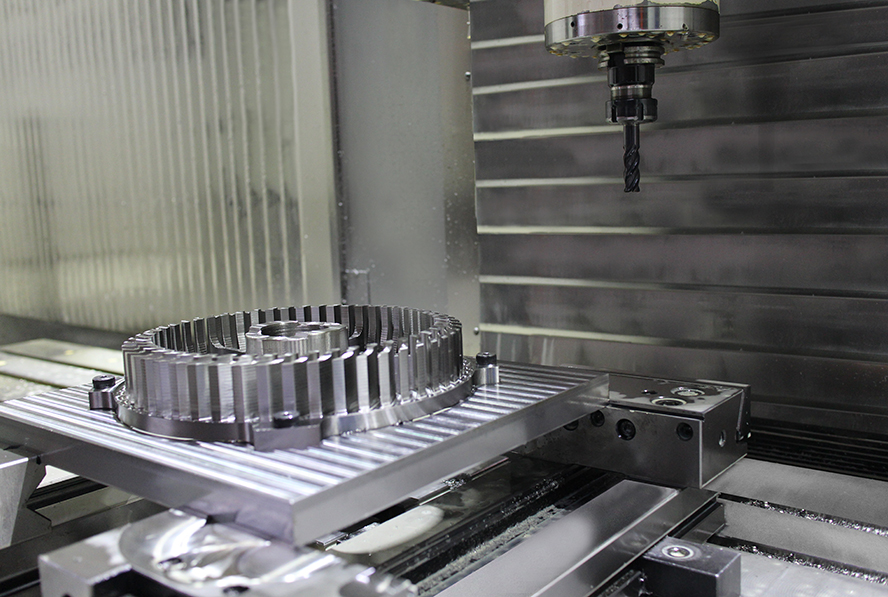

Industrial Mechanical Processing

Osca Automazioni uses EDGECAM software for its mechanical processing - a CAD/CAM system with continuous 5-axis and compatibility with all Inventor, STP, and IGS files - which ensures a high degree of precision and productivity of its machine park on the following materials used:

- Aluminum

- Iron

- Cast Iron

- Titanium

- Stainless Steel

- Alloy and non-alloy steel

- Alloys in general

In addition, thanks to the experience of its operators, the company also offers milling, turning, and grinding work.

Technical Coatings

The use of technical coatings suitable for the required application facilitates the advancement of the product to be fed, allowing a significant reduction in the level of noise, as well as the preservation of the details to be fed.

Thanks to the experience gained over the years, Osca Automazioni is able to choose the most suitable coating for each specific use, drawing from a wide range of technical coatings in its possession, different in characteristics, thicknesses, and hardness, among which:

NBR rubber with knurls

Smooth NBR rubber

Polyurethane

Reversed PVC

Friction-based PVC U21

Double-cloth smooth PVC U21

Spherical knurls PVC

Unidirectional bristle carpets

PTFE teflonation for food contact

Elastomers

Spray polyurea

Metal coating with sound-absorbing characteristics

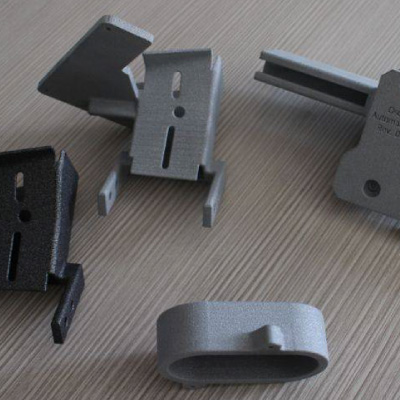

3D Printing

Osca Automazioni is capable of creating components from simple and essential shapes, to extremely complex geometric forms, impossible to achieve with traditional technologies.

Each single element is made with durable and resistant materials with characteristics of precision, repeatability, and stability over time, which guarantee high quality standards to the final product.

Furthermore, the company, in order to meet its customers' demands, offers resources and tools aimed at creating components using 3D printing methods.