Vision machines

Vision Machines

Quality Control Vision Machines

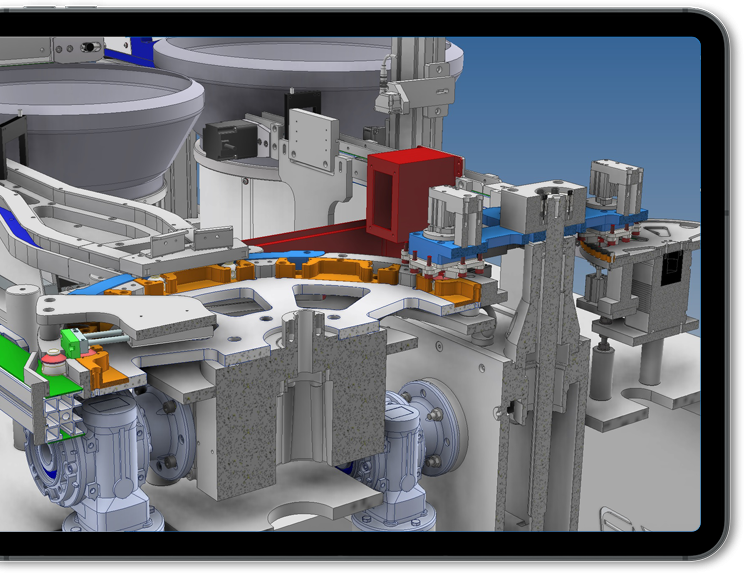

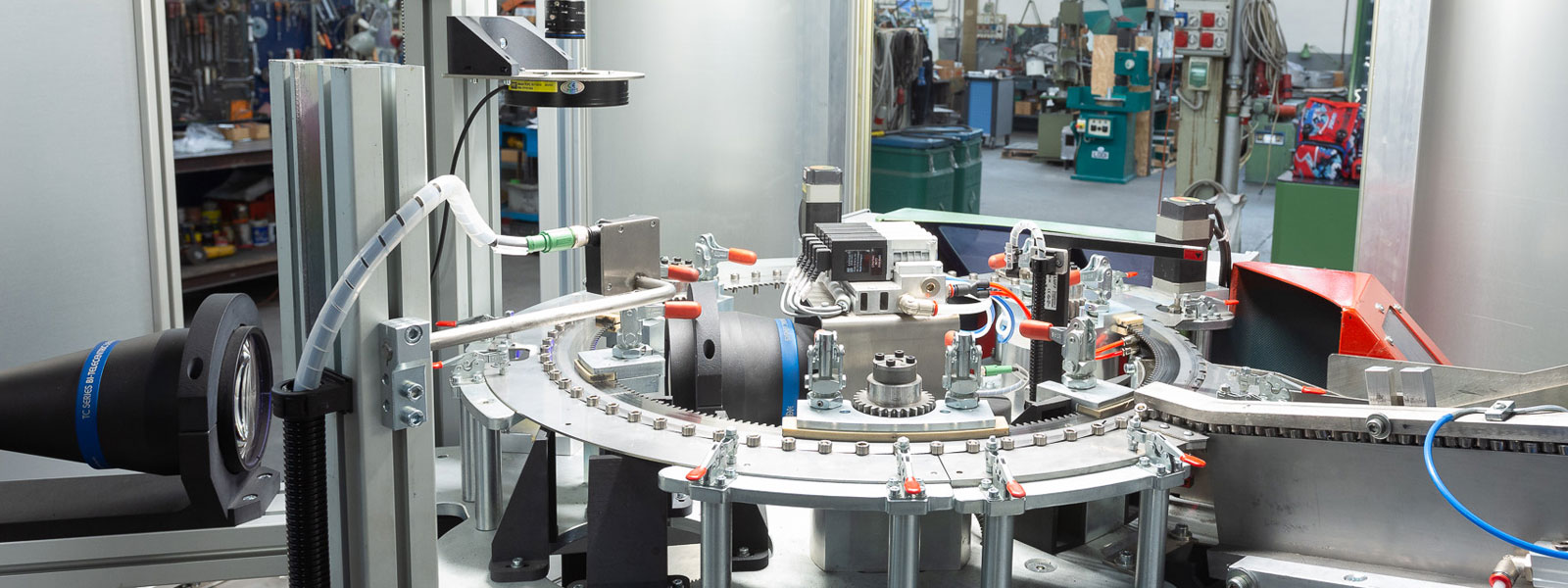

Continuous innovation, combined with advanced digital technologies, allows Osca Automazioni to be a leader in the field of quality control vision machines, without direct contact with the product.

We are able to design and build versatile and modular machines with high control speeds, allowing great flexibility in the control processes for various types of products (metal small parts, fastening screws and bolts, items with complex geometries, rivets, threaded rivets, bushings and sleeves, etc…).

In this way, we can achieve and guarantee high quality standards in the selection and/or classification of the product, in addition to consequent reductions in production waste.

Specifically, Osca Automazioni offers 4 different series of control machines, which can be used throughout the production cycle, from the product's inbound acceptance, after certain work phases, to the control of the finished product.

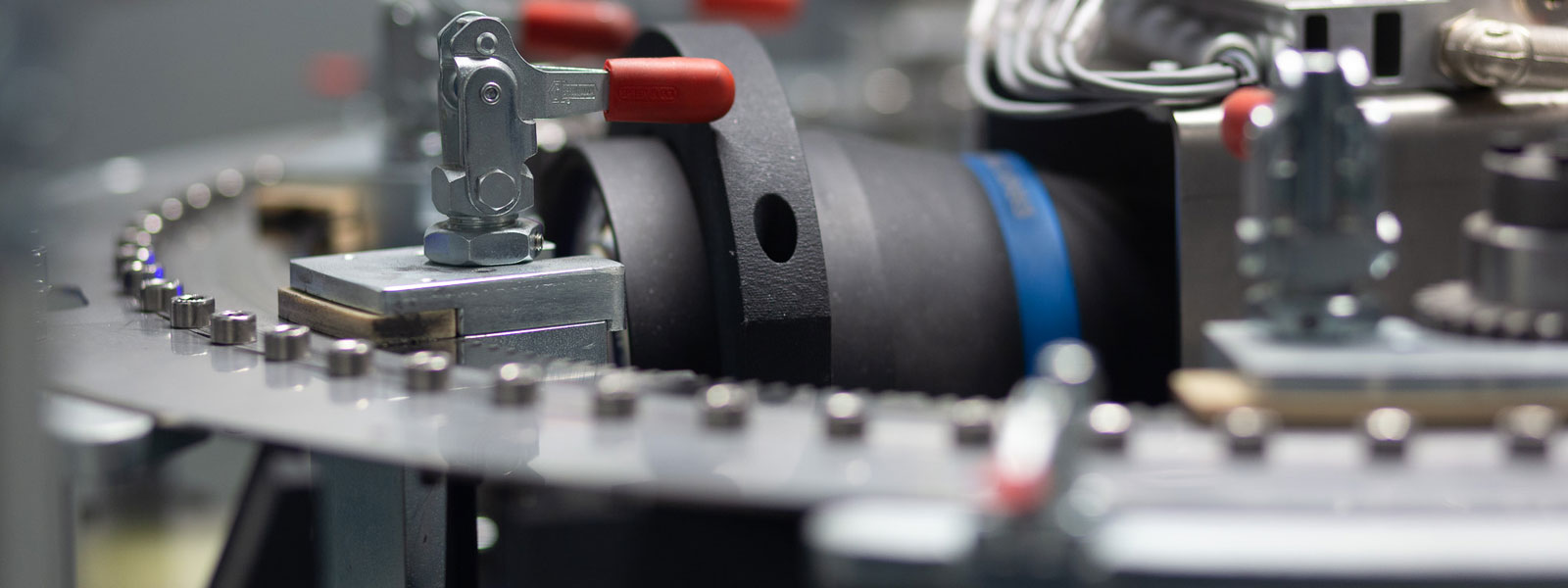

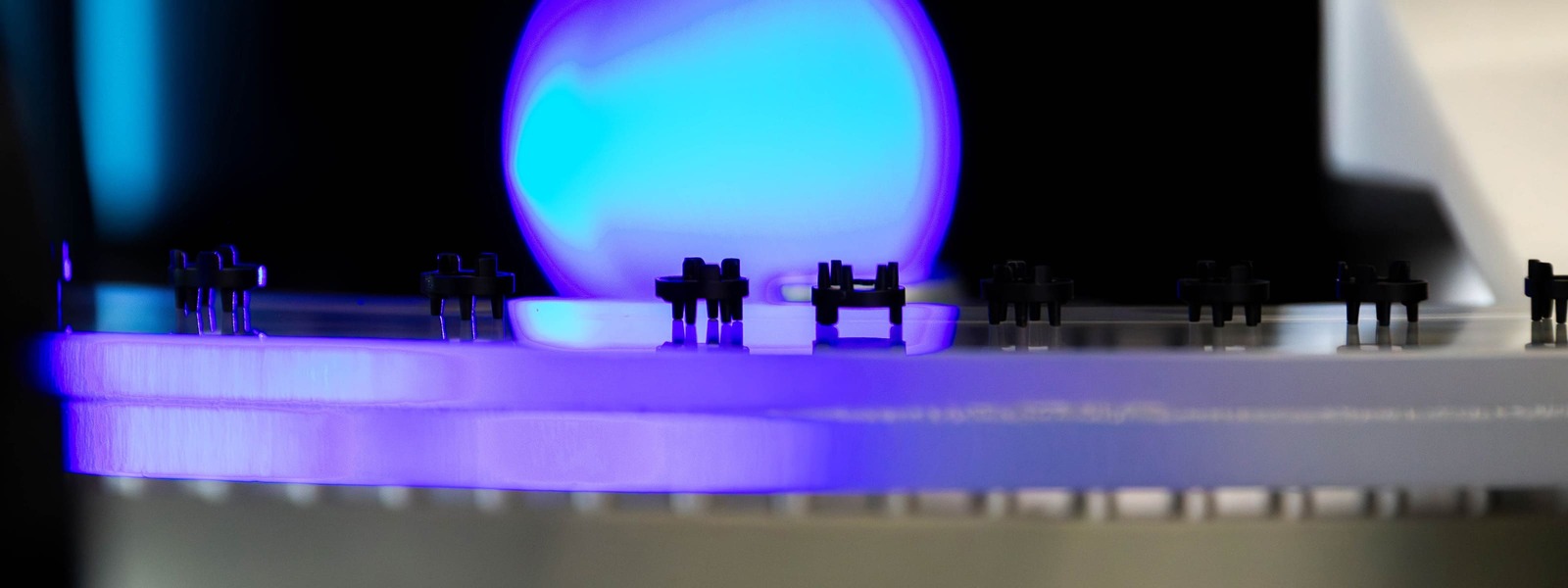

The visual inspection machines of the Sirio Series are designed for dimensional and surface checks of screws, rivets, threaded rivets, bushings, and sleeves on rotating glass tables with a diameter of 600mm.

Specifically, the Sirio 600 is an extremely flexible machine with versatile and fast feeding systems, with very short changeover times.

Controllable objects

Screws, rivets, threaded rivets, bushings, sleeves, pins

3 < Dg < 20mm

Machine specifications:

Inspection Specifications

Machine Management Specifications

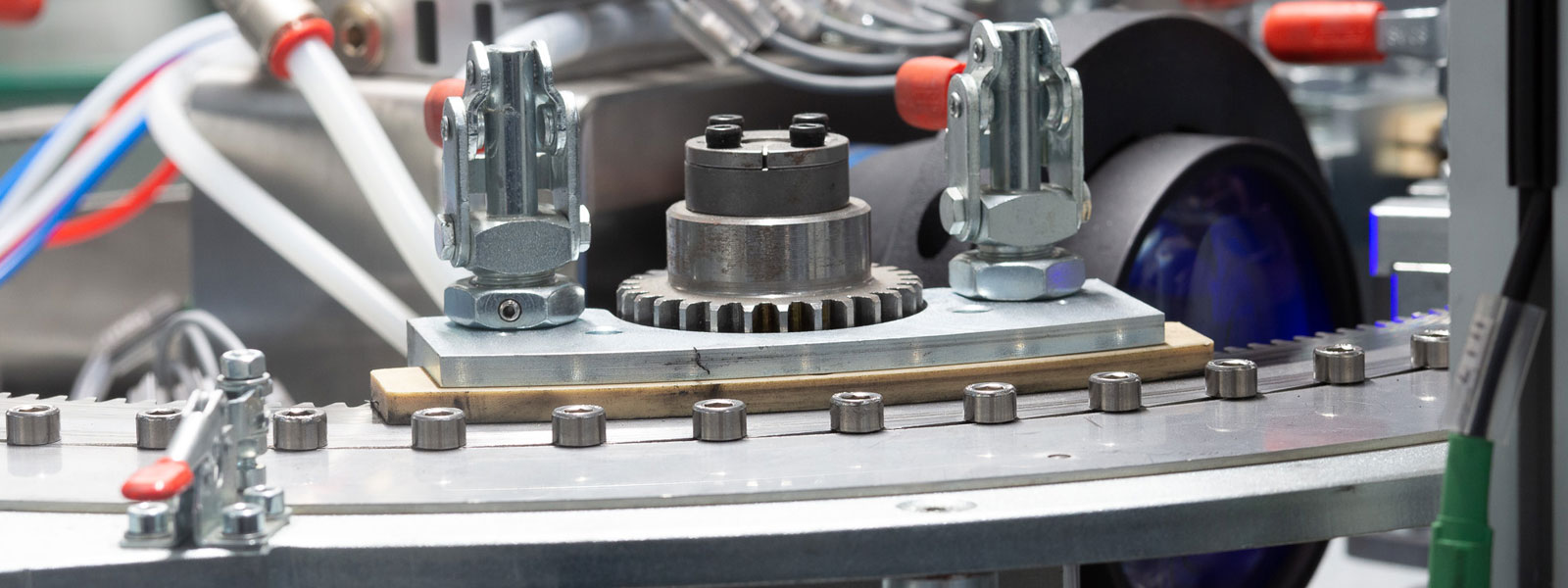

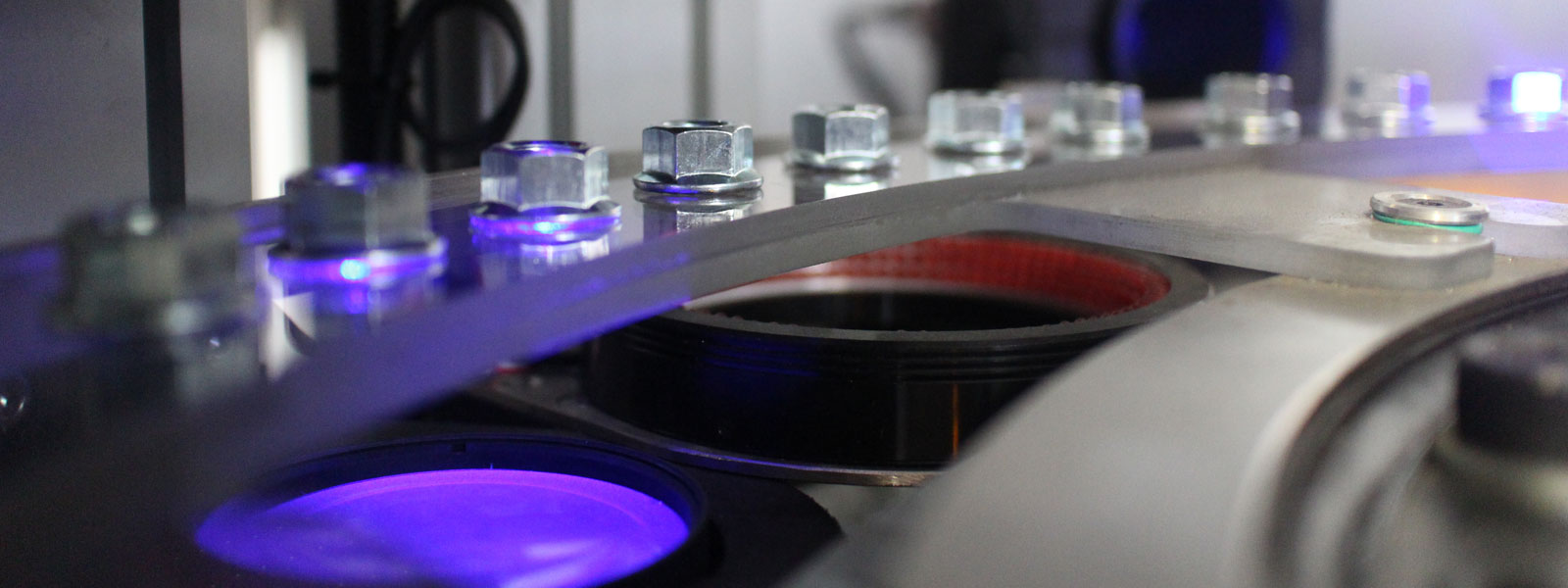

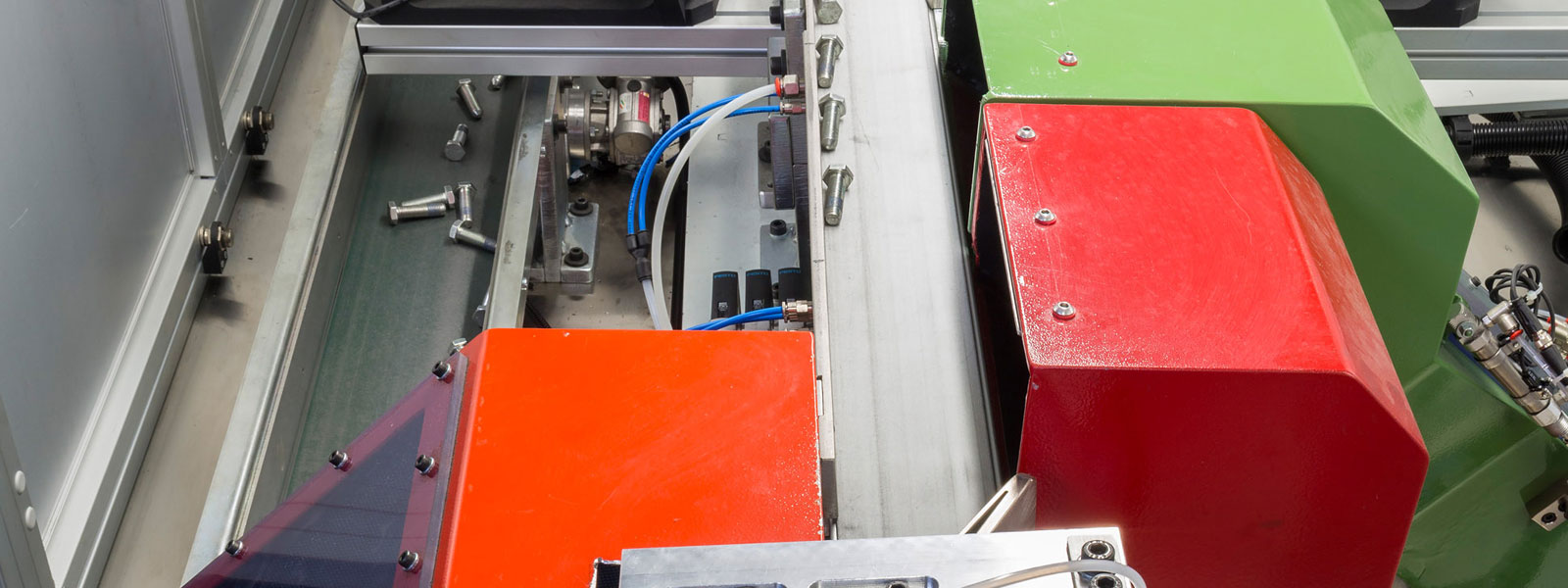

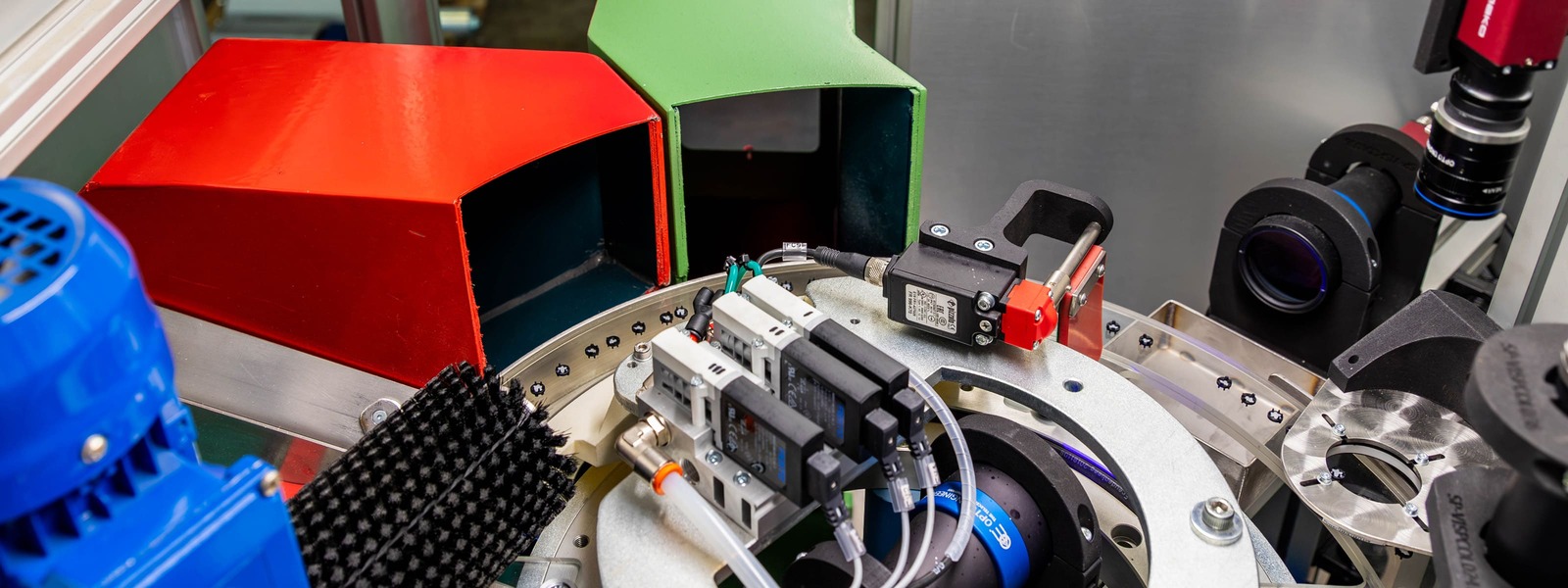

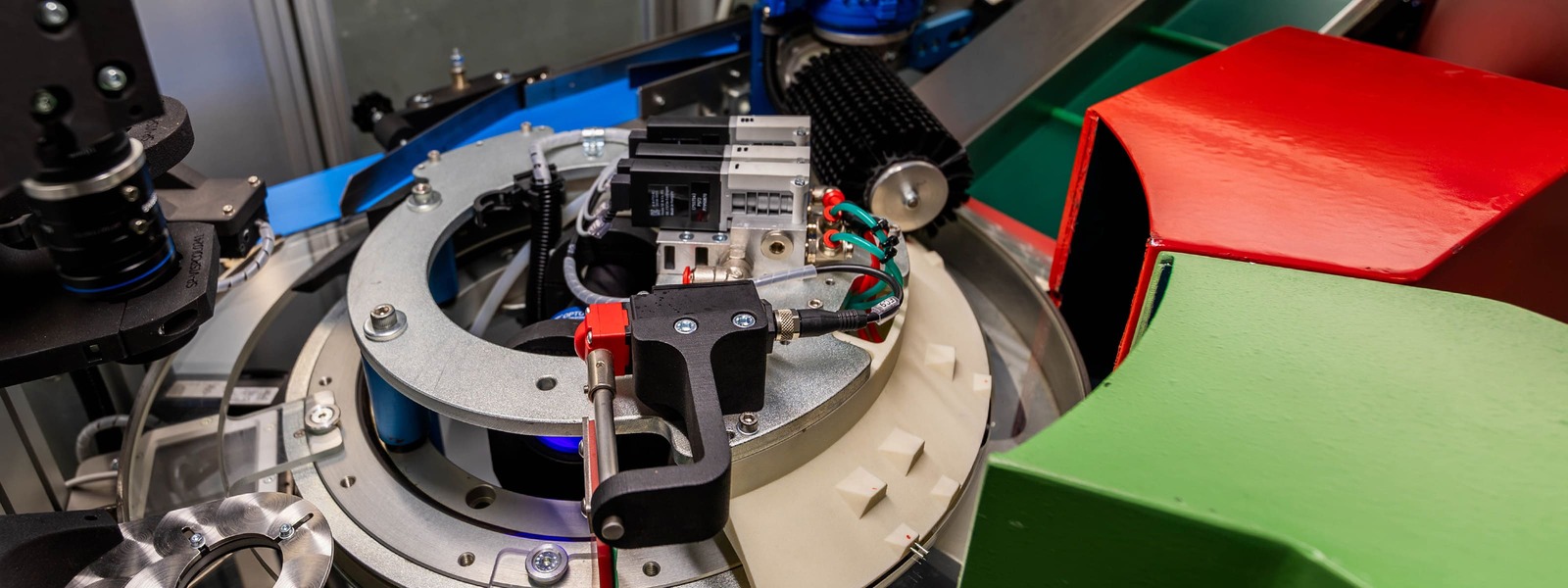

The Saturno 850 series consists of visual inspection machines, with a rotating glass disk with a diameter of 500mm, designed for dimensional and surface checks of various types of small parts (fasteners, screws and bolts, parts with complex geometries, rivets, bushings, sleeves, etc...).

This type of machine is characterized by its flexibility and versatile feeding systems, which are fast and have very short changeover times.

Controllable objects

Machine specifications:

Inspection Specifications

Machine Management Specifications

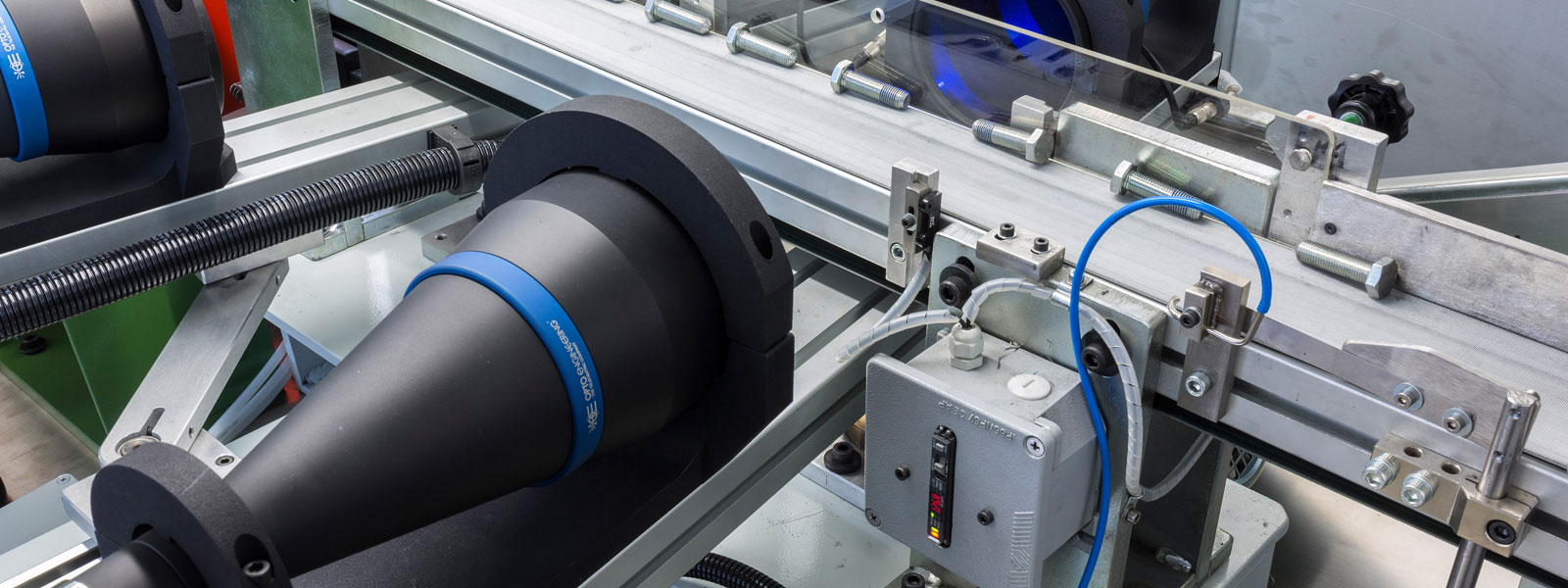

Orion Series

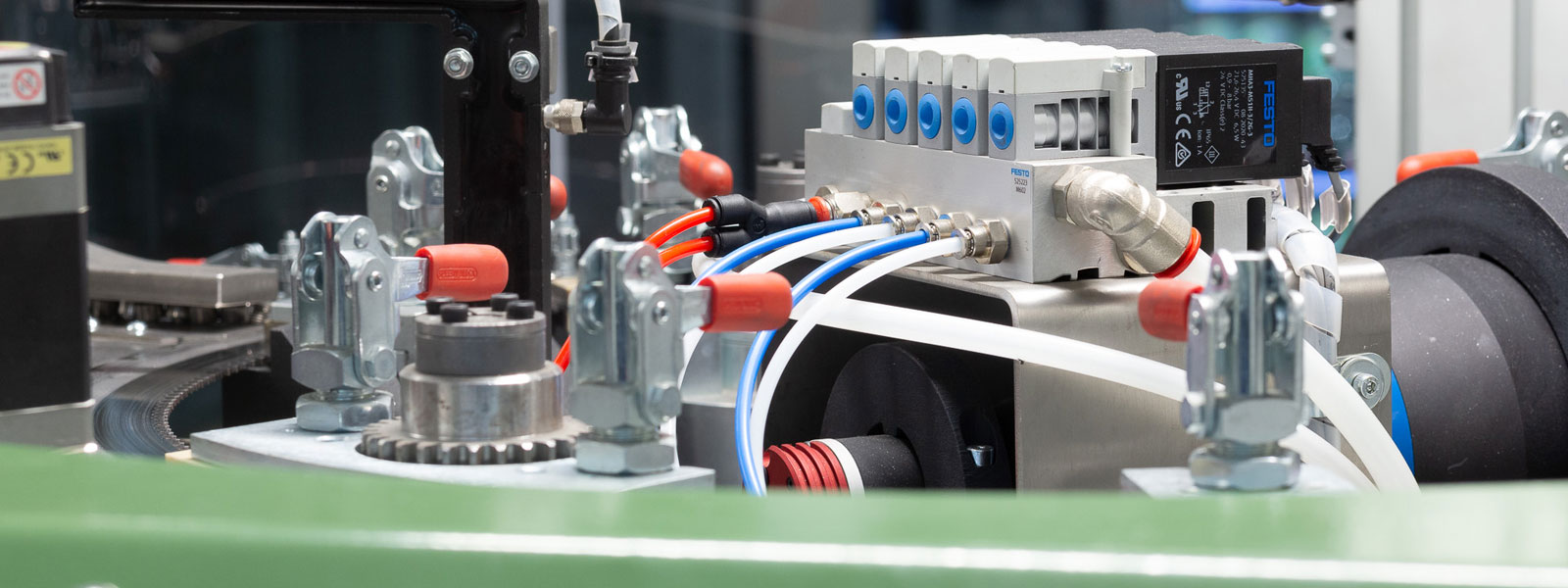

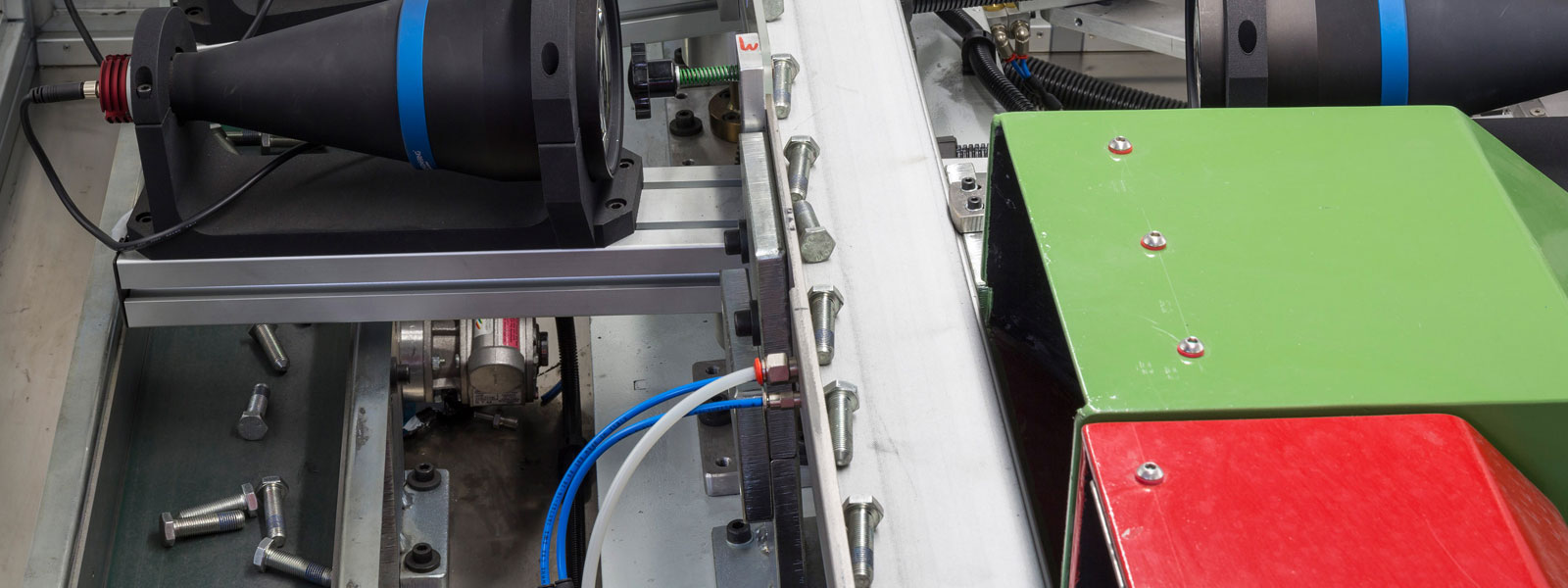

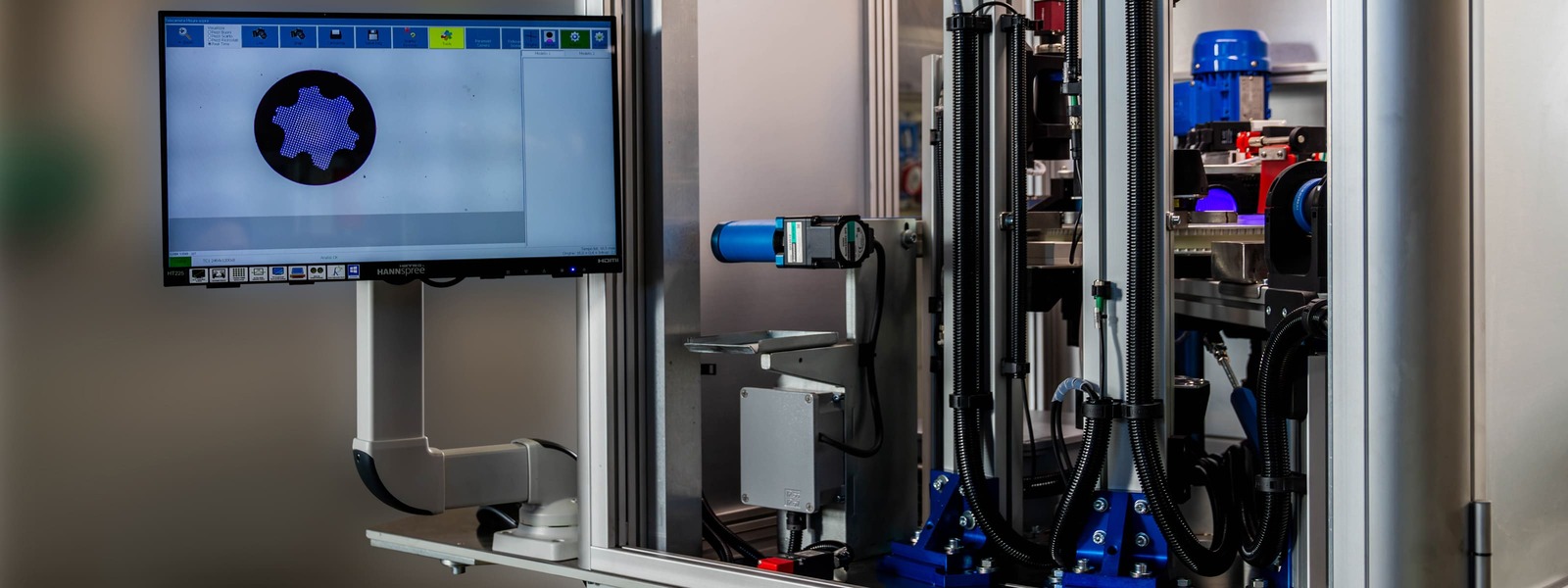

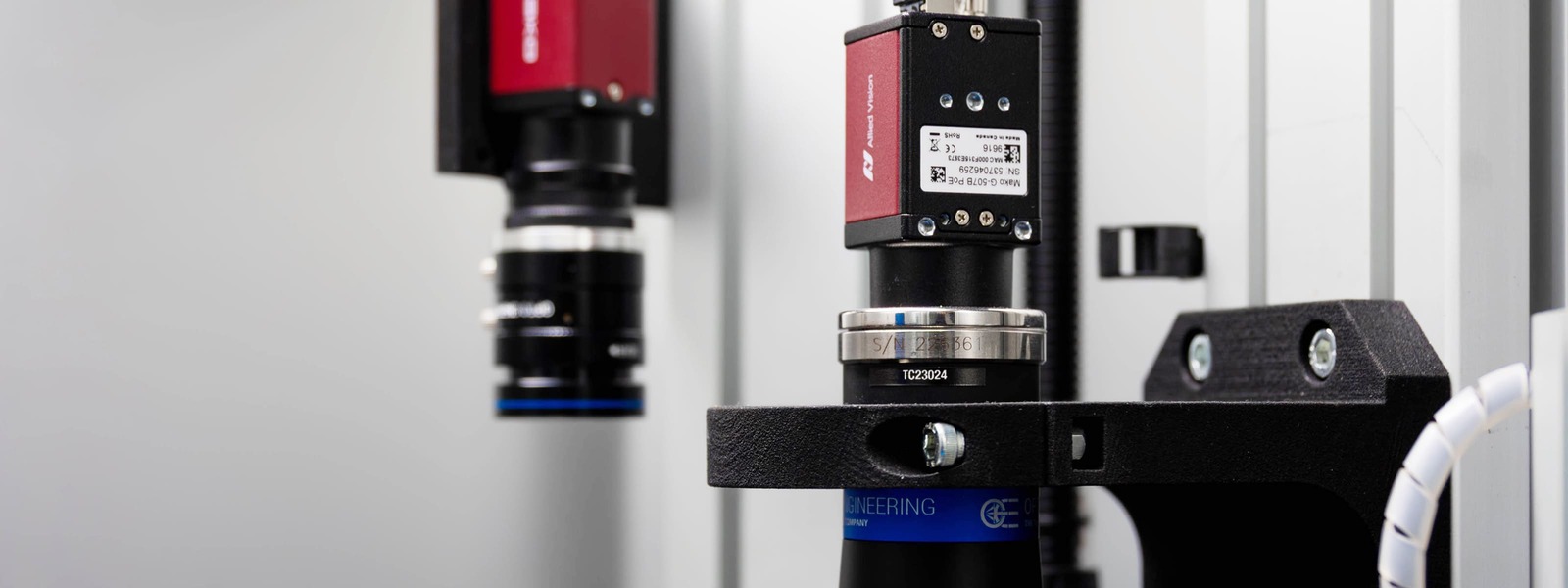

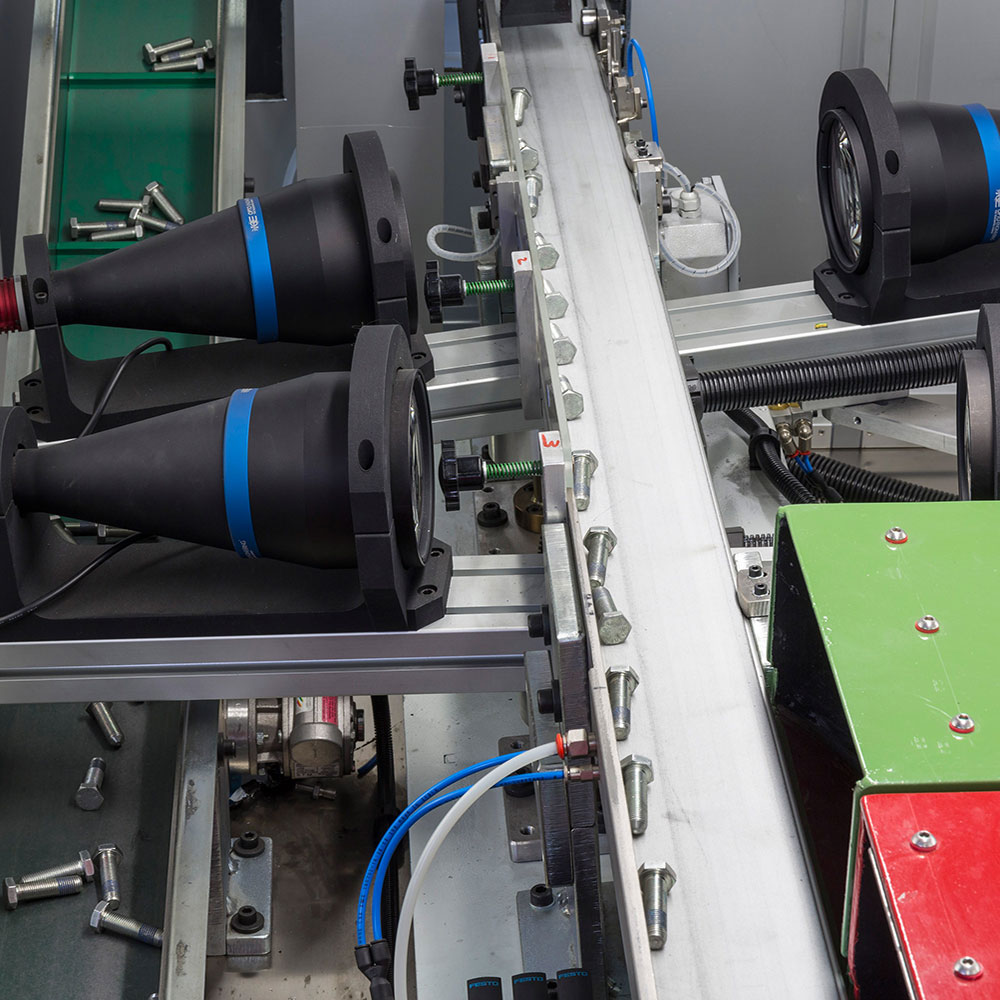

The Orion Series vision machine is a versatile visual inspection plant on tape with two/three cameras, used for dimensional and surface control at speeds of up to 600 pieces/min.

The Orion Series is ideal for producing various types of small parts: from fastening elements (screws and bolts), to parts with complex geometries, ensuring a versatile and fast system, whose changeover times are minimized.

VISION MACHINES - ORION SERIES

Potential readiness for:

- Dimensional checks also on complex geometries

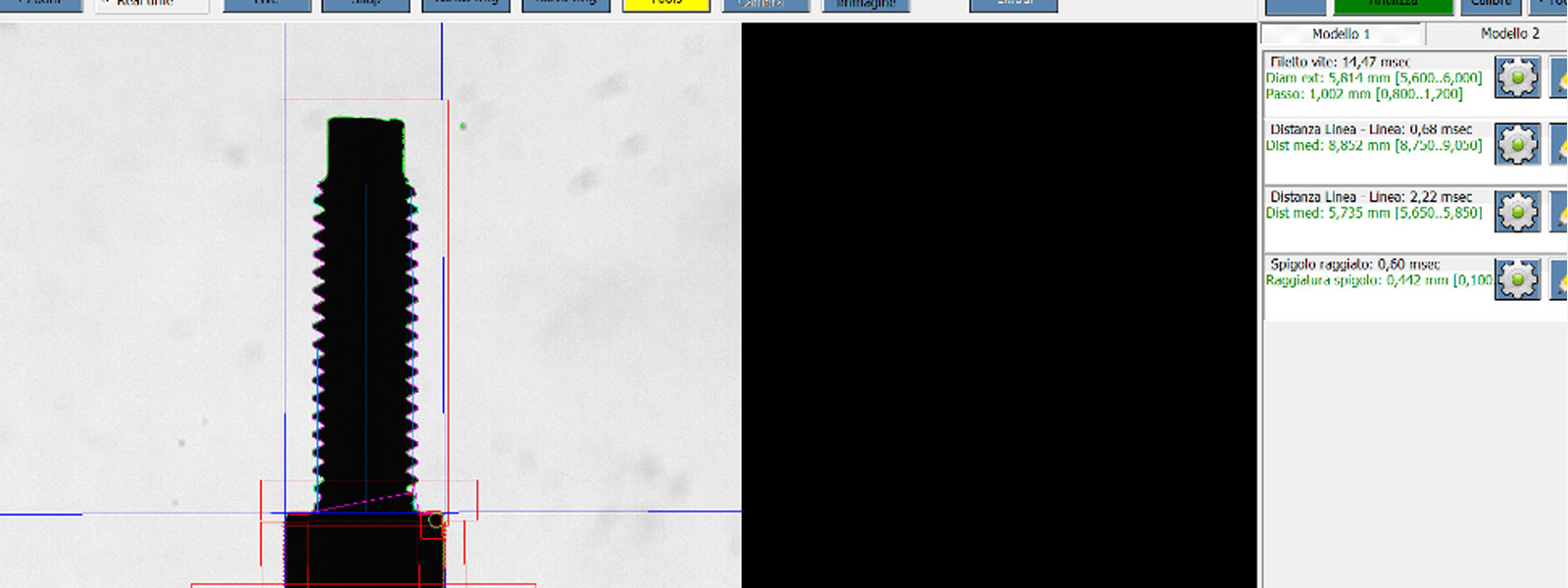

- External threading checks

- Integrity control of external threads with precise measurements

- Presence check of internal threads

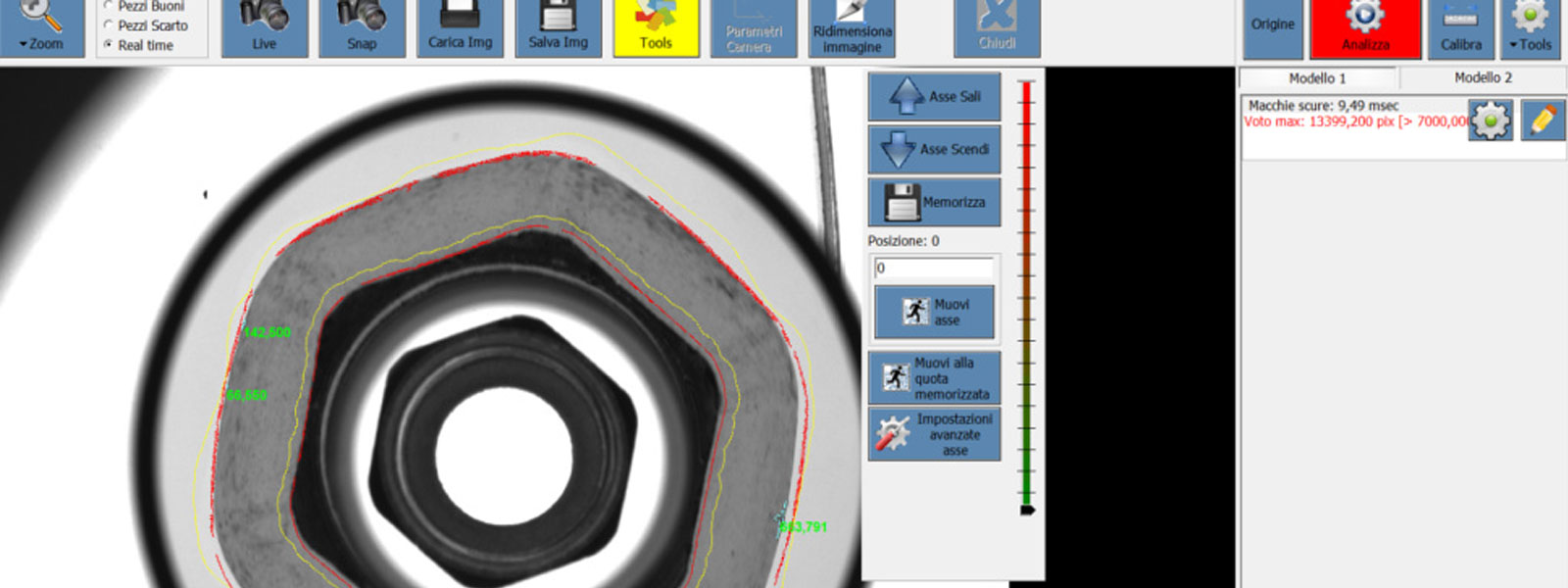

- Piece inspection to identify engravings and cracks on front and side surfaces

- Piece inspection to identify surface engravings and scoring

- Presence check of machining burrs

- Color control and recognition

- Dedicated management software, with a user-friendly operator interface, for piece counting function, reports (statistics) and histories that can be integrated into management systems (developed in collaboration with Vision srl)

- Preparedness for remote assistance

VISION MACHINES - ORION SERIES

Possible implementations:

- Additional control stations

- Servo systems for the feeding group

- Packaging system

- 3D Laser for checking thickness and planarity of objects

Saturno 500 is a visual inspection machine, with a rotating crystal disc of 500mm in diameter, designed for dimensional and surface checks of various types of small parts (fastening elements, screws and bolts, parts with complex geometries, rivets, sleeves and bushings, etc...).

This type of machine is extremely flexible and equipped with versatile, fast feeding systems with very short changeover times.

Controllable objects

Machine specifications:

Inspection Specifications

Machine Management Specifications